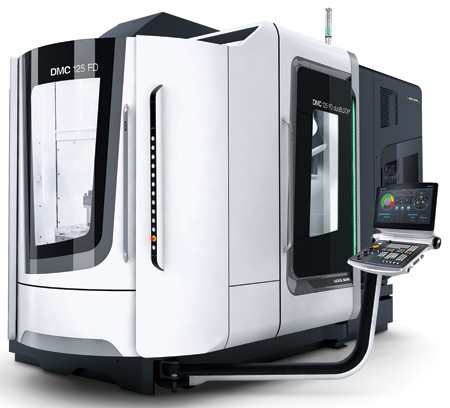

5X torqueMASTER with 1,800 Nm and 52 kWĮfficiency Grinding Options In Dmg 125 Fdw Grinding Options In Dmg 125 Fda.powerMASTER motorspindle with 1,000 Nm and 77 kW.Sizes 80, 125 and 160 in the duoBLOCK FD series, both the DMU. Also available in mill- /turn - version The addition of grinding on the same machine platform will be of particular interest to manufacturers wishing to take advantage of single set-up metalcutting to preserve dimensional accuracy and combine it with high quality surface finishes down to 0.4m achievable with grinding.Up to 50 % higher cutting power with the roughing package.Significantly improved temperature response.SGS: Spindle Growth Sensor for Compensation of spindle increase.Maximum accuracy through completely water-cooled feed drive.Best surface quality with technology integration grinding.Milling and turning in one setup with the DirectDrive table and rotational speeds up to 500 rpm.Equipped with “Best in Class” FD-table with up to 500 rpm and 3,982.0 ft./lbs., as well as the innovative wheel magazine, it offers high machining performance and a space-saving pallet changer. The DMC 125 FD duoBLOCK® 4th Generation sets new standards for 5-sided and 5-axis simultaneous machining. Optimale Wartungsfreundlichkeit und beste Ergonomie durch uneingeschränkte Zugänglichkeit. Every DMG MORI machine can be upgraded with standard automation or with a customized automation solution for flexible manufacturing systems. Geringer Platzbedarf, extrem kompaktes Radmagazin mit kürzester Bereitstellungszeit von max. This can be equipped with 12 components on two levels, ensuring long-term, unmanned operation. For example, the 5-axis CNC turning machine DMC 125 FD duoBlock is coupled to a RPS 12 system. This saves space and ensures shorter installation set-up times. All three machines also have an automated pallet changer. Every DMG MORI machine can be upgraded with standard automation or with a customised automation solution for flexible manufacturing systems. an ULTRASONIC 125 FD 2: Outer- and inner cylindrical grinding. Vertical Mate 125 - Vertical Grinding Machines and Vertical Grinding Centers by DMG MORI. The ULTRASONIC technology from DMG MORI enables the economical machining of complex work. Low space requirements, extremely compact wheel magazine with short tool replenishment time of max.

0 kommentar(er)

0 kommentar(er)